1. Overview of the use of pool circulation pump in swimming pools and recreational sports

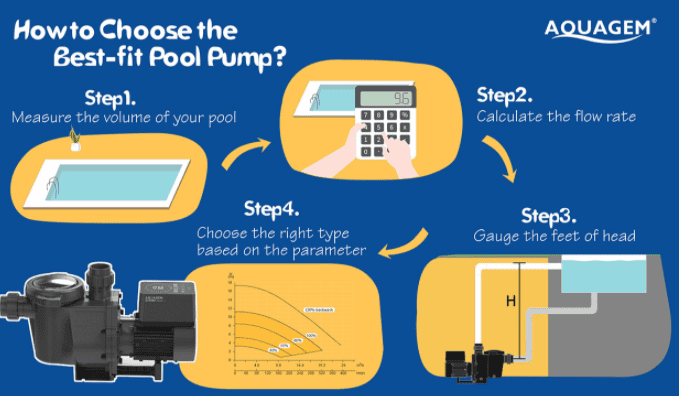

The pool circulation pump is like the heart of the human body to the circulation filtration system of the swimming pool. It is the hub for the normal operation of the system. Choosing an energy-efficient pool pump must start with its most important performance parameters. The main performance parameters of the pool pump are flow, head, power, and efficiency. For a specific swimming pool and SPA system, they work differently with each other. Only by grasping the state of the water treatment system and its changing laws, can the right pump be selected so that the equipment operation and the water treatment effect are in the best condition.

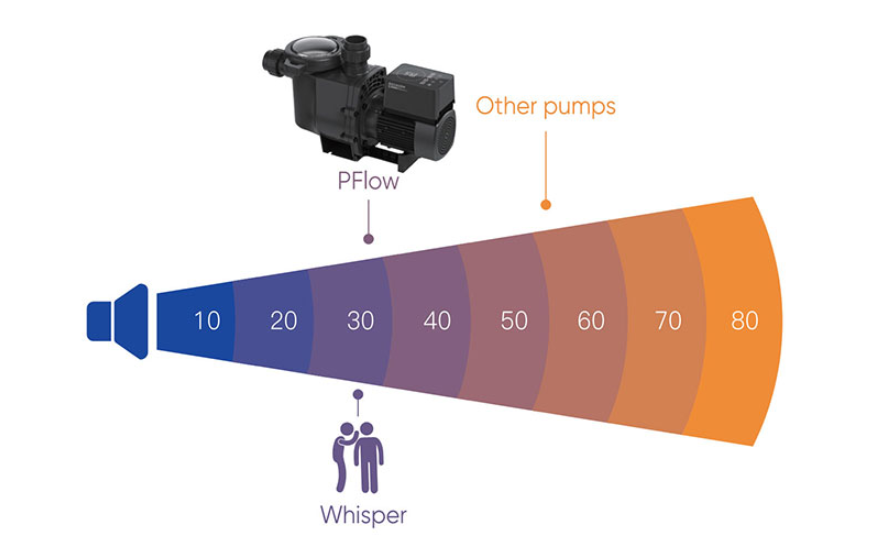

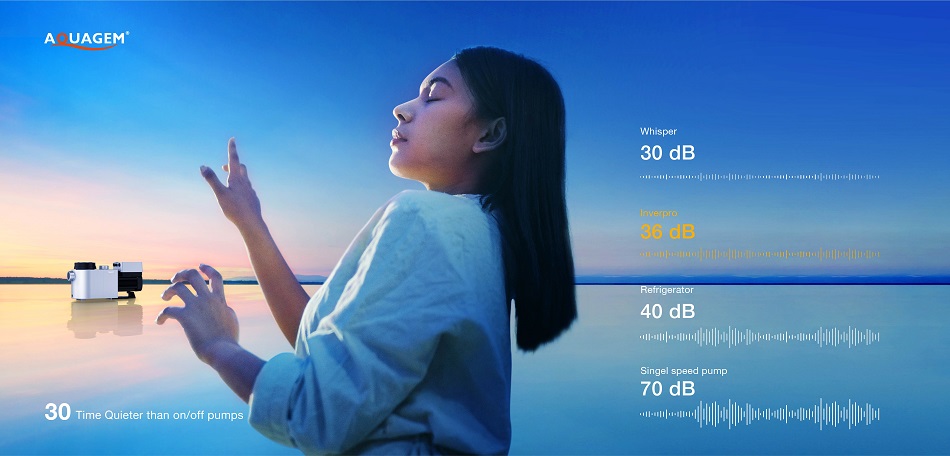

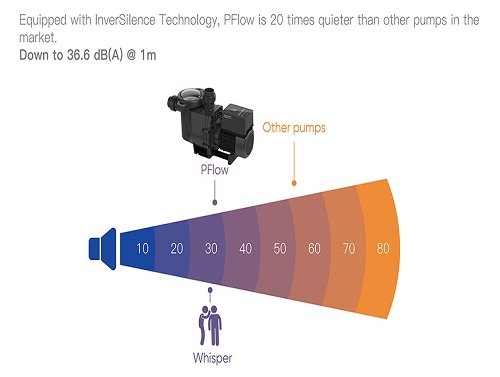

Swimming pool circulation pump: Swimming pool water pump has its particularity: large flow and low lift-advantages: the filtration system of the entire pipeline system is stable and saves electricity. High-power water pool pumps are recommended to use low-speed water pumps: the advantages are stable operation, low noise, and electricity saving. The selection of the pool pump must be matched according to the performance curve.

2. Main performance parameters of a centrifugal pool circulation pump

Because the circulating pumps and functional pumps of swimming pools and spas are designed as self-filling, the allowable suction vacuum height and cavitation volume of the water pump can be ignored. The main performance parameters are: flow, lift, shaft power, and efficiency.

2.1 Flow rate Q[m3/h]: The flow rate of pool filter pump is the amount of water output through the water outlet of the water pump per unit time. Of course, it is a measure of the potential energy and kinetic energy obtained by the pump resisting the pressure of the circulating filter of the entire system, so the flow rate is for the flow under a certain head, different pressure heads have different flow rates. When the head is high, the flow is small, but when the head is small, the flow is large.

2.2 Head H[m]: also known as the pressure head of the swimming pool filter pump, the energy obtained by the unit weight of liquid flowing through the pump. The pressure head of the system has a certain range of change in a specific swimming pool circulating filter system. At the initial filtration, the pressure head of the system is small, and the flow is large at this time; after a period of operation, the interception of the filter gradually blocks the water flow. The pressure head becomes larger and the flow rate becomes smaller correspondingly. For pumps with the same pipe diameter at the inlet and outlet, when the vacuum gauge on the suction pipe and the pressure gauge on the outlet pipe [1] are installed at the same level, the pump lift is the sum of the suction and pressure. Factors affecting the size of the pump head: 1. Pump structure (impeller size, degree of bending); 2. Rotation speed; 3. Flow rate.

2.3 Shaft power N[Kw]: The power transmitted by the motor to the pump shaft, that is, the power consumed by the pump shaft.

2.4 Efficiency η[%]: The ratio of the effective power Ne (referring to the power of the mechanical energy obtained by the fluid) of the swimming pool pump to the shaft power is called efficiency, η = Ne / N. Since the pool pump cannot transfer the power input from the motor to the water flow without waste, energy loss is bound to occur in the swimming pool water pump. Therefore, efficiency is used to measure the magnitude of the energy loss and the degree of effective use of energy. The reason for the energy loss: 1. Volume loss; 2. Hydraulic loss; 3. Mechanical loss, etc.

3. Characteristic curve of centrifugal swimming pool water pump

3.1 H-Q curve, also called head curve: The head curve of a water pump is a descending curve, and the flow rate gradually decreases with the increase of the head. The characteristic curve is commonly used when selecting pumps.

3.2 NQ curve, shaft power curve: it is a rising curve, the measured shaft power N increases with the increase of the flow rate Q, when Q=0 (the outlet valve is closed), the minimum shaft power N=Nmin, at this time it is called It is the no-load power. Close the outlet valve and start

Purpose: To prevent the motor from overloading and burning out, and to reduce the impact on downstream equipment such as filters and pipe fittings.

3.3 η-Q curve, efficiency curve: The measured efficiency curve has a trend of decreasing from the highest efficiency point to both sides. When the flow rate changes from small to large, the efficiency curve first rises and then falls, which is a curve with extreme points. The design working point of the water pump should be the highest efficiency point, and its corresponding value is called the best working condition parameter. The range of the high-efficiency zone: η real = (0.7-0.9) η. Choose a centrifugal pump to work in the high-efficiency zone as much as possible.

“Swimming pool water pump head should not be less than the sum of the geometric height of the water delivery and the circulation system equipment, pipe resistance, and outflow head; the pump head should be selected by multiplying the calculated head by the guarantee factor of 1.10.” In the design and selection, it is necessary to choose a sufficient surplus head. It is necessary for the pump to work normally in the high-efficiency area. However, in the actual engineering design and calculation, due to lack of serious research and analysis, in many cases it is taken for granted and subjectively imagined the working status of the swimming pool system. As a result, the water pump has running problems and poor filtering effects, or increased operating costs. , Even the water pump does not work properly.

In the actual engineering of swimming pools, the pump head is generally high and often runs in an inefficient state without being noticed, and some cannot operate normally, ignoring the harm caused by the excessively high surplus head to the pump itself, so the pump is in use Some of the problems that appear in the system are often directly related to the initial design and selection. The correct selection of the pump head is essential for its normal and efficient operation.

4. Pool circulation pump head and head experiment

“The suction pipe of each swimming pool circulation pump should be equipped with a negative pressure vacuum gauge; the outlet pipe should be equipped with a pressure gauge.” As the suction and outlet pipes of the swimming pool pump are installed with a negative pressure vacuum gauge and a pressure gauge, The readings of the pressure gauge and vacuum gauge during the circulation filtration can accurately measure the head of the pool circulation pump and the pressure of the system, so as to find out the flow rate of the water pump according to the water pump curve.

The head of the swimming pool water pump is calculated under atmospheric pressure. If there is back pressure ozone dosing into the booster pump or the pressure head loss of the booster pump of the heat exchanger, it cannot be simply pressed down according to the atmospheric pressure. Since no attention is paid to the particularity of swimming pool engineering, in the engineering design of swimming pools and spas, the calculated heads of circulating pumps and functional pumps are often selected too high, which is far from the actual working state of the system. When the actual working head of the water pump is significantly lower than the rated working head, the flow rate of the water pump will increase greatly, causing the power of the water pump to exceed the power of the motor, causing it to generate heat or even damage the motor, and also cause the actual flow rate and filtration rate of the sand tank to exceed Great, affect the filtering effect.

4. The problem of the surplus head of the pool filter pump

As mentioned above, the head of the water pump includes the suction head and the discharge head. If the actual flow rate of the swimming pool filter pump and the efficiency η corresponding to the head point is ≥(0.7-0.9)η, it can be considered that the pump is in a high-efficiency operation state. The area that meets this condition can be called the high-efficiency operation area of the pump. In the operating area, the relationship between the various parameters of the pump has a performance curve that meets the design requirements.

4.1 Working point of water pump and piping system: For the piping system, the friction force of the inlet and outlet pipelines and pipe fittings has a great relationship with the flow rate. Within a certain range, a certain pressure needs one corresponding to the flow rate, and the flow rate continues to increase. The corresponding pressure also increases. Therefore, in the pipeline system, the characteristic curve of pressure and flow is a parabola with an opening upward. The intersection point of the characteristic curve of this pipeline and the relationship between the head and flow in the pump is our working point of the pump to be studied in a certain pipeline.

4.2 The actual working point of swimming pool circulation pump when the surplus head is in the design of the water treatment system if the excessive surplus head H3=25m is selected, the flow rate at this time is Q3, which corresponds to the optimal filtration speed of the design; but When the system is running, it is found that the maximum actual pressure head loss of the system during backwashing is H2=15 meters, and the flow rate at this time is Q2, and its corresponding filtration speed is greater than the optimal filtration speed designed; but it is back after the backwashing The smaller head loss of initial filtration H1=9 meters, the flow Q1 at this time is much larger than the design flow Q3, which may double the actual filtration speed. From the inverse relationship between filtration speed and filtration accuracy, it can be seen that the actual filtration speed corresponding to Q1 is much greater than the filtration speed corresponding to the design flow Q3, so the actual filtration effect is greatly reduced.

If the head we choose is too surplus, the actual working point and the designed working point will have a big deviation, there will be many problems, and it will affect the normal operation of the pump and the filtration accuracy of the sand tank. The hazard of the excessively high surplus head, in some cases, is not only a problem of serious overload and reduced efficiency but also induces vaporization and cavitation due to increased flow, which affects normal operation. The main method to solve this problem is to adjust the valve at the outlet, reduce the opening degree, and move the actual working point to the designed working point. At this time, all the surplus head is consumed on the outlet valve, the pipeline loss increases, and the efficiency of this system is significantly reduced. This is very uneconomical.

5. Lifts of circulating pumps and functional pumps in swimming pools and spas

For the self-filling circulating filtration system with the height difference between the swimming pool and the computer room within 5 meters, if the pipeline is designed according to the standard of fluid mechanics, according to statistics, most of the initial filtration pressure head is (0.8- 1) ±1bar, the backwashing pressure head is (1.2-1.4) ±1bar, the maximum backwashing pressure head is 1.5±1bar, so the pump head is selected at 15-17 meters to meet the general normal swimming pool circulating filtration conditions (Already include 1.10 times the head guarantee factor). For the selection of the head of the functional pump, the actual pressure and flow rate at the outlet of the nozzle should be measured, and the working state of the pump should be adjusted to reach the designed pressure and flow rate.

6. Tips for using swimming pool water pump

When the surplus head of the swimming pool and spa water pump is too large, it will affect the filtration accuracy and cause human injury, and it will also overload and overheat, burn the motor, vaporize and cavitate, and damage the pump and pipeline system. For newly designed swimming pools and spas, the head should be calculated after comprehensive consideration of various factors according to the actual project, which cannot be taken for granted. For the system that is already in operation, check the readings of the vacuum gauge before the pump and the pressure gauge after the pump to determine the actual working system pressure head. If there are major problems, the necessary treatments are as follows:

6.1 Replace the swimming pool filter pump and choose a water pump that is close to the actual working head and flow.

6.2 Cut and reduce the outer diameter of the impeller, reduce the rated head of the pump, and make it close to the actual working head of the pump.

7. Matters needing attention in the specification of circulating water pump

7.1 The pool filter pump of the pool water circulation purification system, the functional circulating water pump of the water amusement facility, and the circulating water pump of the waterscape system shall be installed separately.

7.2 The selection of pool circulation pump should meet the following requirements:

(1) The rated flow of the pump should not be less than the calculated circulating water flow of the pool water circulating purification treatment system to ensure the required flow of the pool water cycle;

(2) The head of the swimming pool filter pump should not be less than the sum of the geometric height of the water delivery, the resistance of the circulating purification treatment system equipment and the pipeline system, and the required outflow head of the water inlet of the pool multiplied by the calculated value of the safety system of 1.10;

(3) The swimming pool pump should be a high-efficiency, energy-saving, corrosion-resistant, low-noise swimming pool dedicated variable-frequency speed-regulating pump;

(4) The circulating water pumps of the pressure particle filter should not be less than two, and backup pumps should be set up and run alternately with working pumps;

7.3 The backwashing pump of the quartz sand filter should adopt the working condition design of the pool water circulating pump working pump and the standby pump in parallel, and check and adjust the working condition parameters of the circulating water pump according to the flow rate and head required during the backwashing of a single filter.

7.4 Function of swimming pool circulation pump The setting of swimming pool circulation pump shall meet the following requirements:

(1) The water pump supplying lubricating water for the slideway must be equipped with a backup water pump and can operate alternately;

(2) When the circulating river push-flow water pump is designed according to the working condition of multiple water pumps running in parallel at the same time, the standby water pump may not be provided.

7.5 The waterscape feedwater pump should be designed in accordance with the operating conditions of multiple pumps in parallel, without the need for a backup pump.

7.6 The design of the pool water purification circulating water pump, the amusement facility function circulating water pump, and the waterscape circulating water pump shall meet the following requirements:

(1) It should be designed as a self-filling type, and each pump should be equipped with an independent suction pipe;

(2) The counter-current circulation should be close to the balance pool; the downstream pool water circulation should be close to the backwater of the swimming pool or the balance pool;

(3) Each pump should be equipped with the following accessories:

a) The suction pipe should be equipped with flexible joints, valves, hair traps, and vacuum pressure gauges;

b) The outlet pipe is installed with flexible joints, check valves, valves, and pressure gauges;

c) A reducing pipe should be installed on the inlet and outlet pipes of the swimming pool water pump before installing other accessories.

(4) A special anti-suction device should be installed on the suction pipe of the pool pump that directly sucks water from the bottom of the pool;

(5) The pool water pump unit and pipeline should be equipped with shock-absorbing and noise-reducing devices.