Setting of swimming pool water pump should meet the following requirements:

1 For swimming pools, water amusement pools, water features, hydromassage pools, etc. for different purposes, the swimming pool filter pump should be set separately;

2 The pool filter pump of the pool water circulation system should be selected based on not less than 2 pool pumps running at the same time;

3 The setting of the standby pool pump should be determined according to the following requirements:

1) The standby pump of the pool water circulation system should be determined after comprehensive comparison with the filter backwash water pump;

2) The swimming pool water pumps of the water feature facilities should not be less than two, and pumps are not required.

4 The lubricating water system of the slideway must be equipped with a backup water pump. When installing more than 3 water pumps, there should be a spare capacity not less than 1/3 of the working pump capacity;

5 The water pump should be located in the same room as the circulating water filtration and purification equipment.

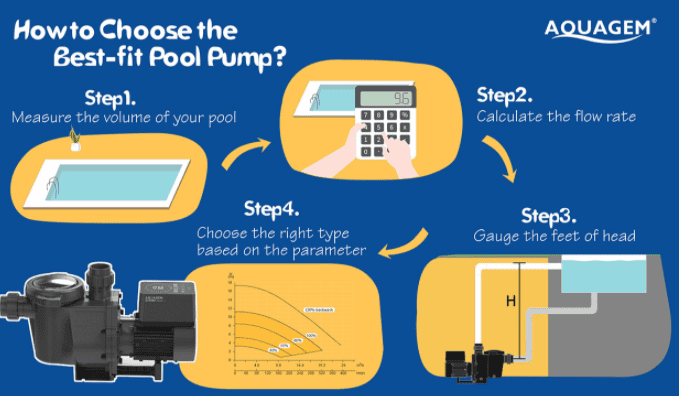

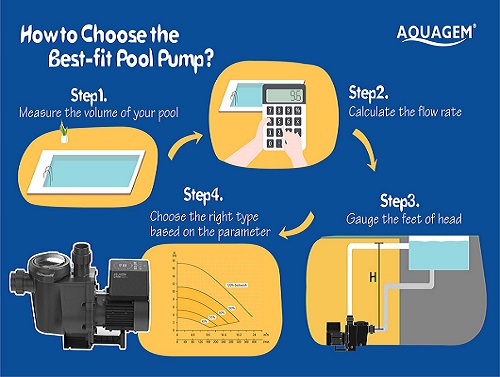

2. The selection of swimming pool circulation pump should meet the following requirements:

1 The pool pump flow rate shall not be less than the regulations;

2 The head of the pool circulation pump shall not be less than the geometric height of the water supply and the filter, hair collector, pipe accessories, water supply port,

The resistance of heater (when equipped), ozone reaction tank, pipeline, etc., and the sum of the outflow head;

3 When conditions permit, low-speed water pumps should be used.

Note: 1 The water features are determined according to the water pose and nozzle product manual.

2 The outflow head of the pool is determined according to the product manual. If this information is not available, it can be selected according to 0.02~0.05MPa.

4 Filter backwash pool circulation pump should adopt the design of circulating water main pump and standby water pump to work in parallel, and the working condition of circulating water pump should be checked and adjusted according to the flow and head required for backwashing.

3. The design of the swimming pool water pump device should meet the following requirements:

1 It should be designed as a self-irrigation type, and should be close to the suction inlet of the balance pool, balance pool or swimming pool, water amusement pool, and water feature facilities;

2. The water flow speed in the suction pipe of the pump should be 1.0~1.5m/s; the water flow velocity in the pump outlet pipe should be 1.5~2.5m/s;

3. Pressure gauges and pressure gauges should be set on the inlet and outlet pipes of the pump respectively;

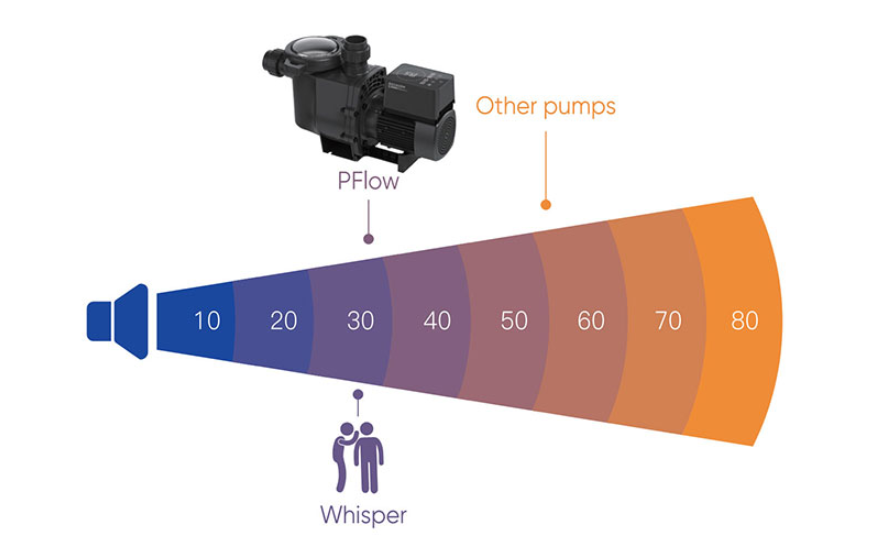

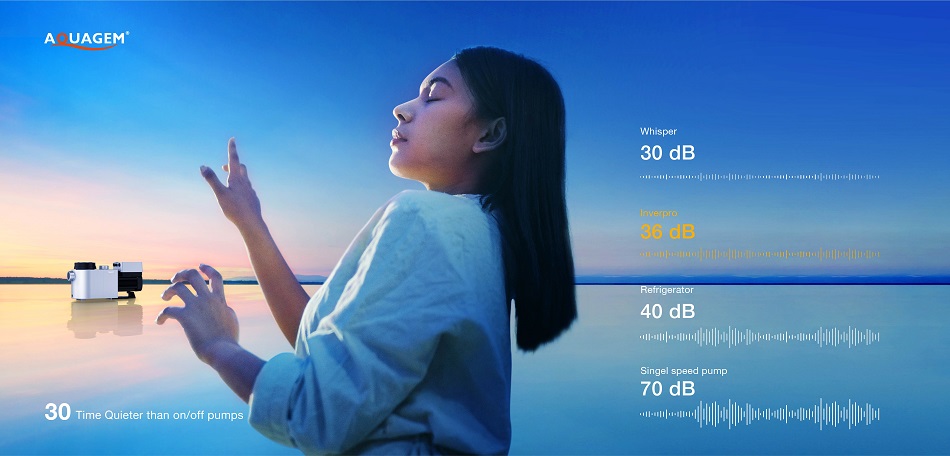

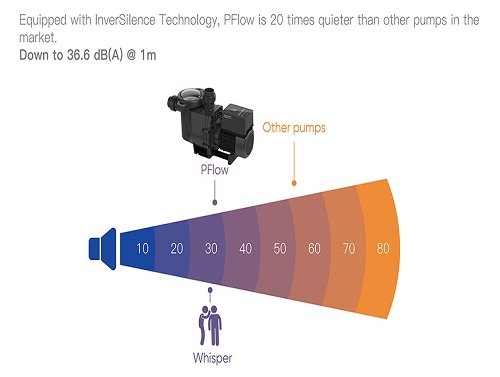

4. Water pumps and pipelines should be equipped with measures to reduce vibration and noise.

5. The circulating water purification system of the competition swimming pool should be stopped during swimming competitions.

Energy-saving operation of swimming pool pumps:

1. minus the running problem of swimming pool circulation pump:

In a system with n circulating pumps operating in parallel, pool managers are likely to reduce the number of swimming pool circulation pumps running at night or during off-season swimming to save power and reduce swimming pool operating costs. But this may cause an overload of the motor running the pump, and burn the motor in severe cases. The selection and design of the pump should consider this situation and take corresponding measures during operation.

In the first example, it is a system with 3 swimming pool filter pumps operating in parallel. If one pump is stopped and it becomes a system with 2 pumps operating in parallel, the working condition area (b2~b2′) of the pump is always in the pump characteristics. In the interval (a~d) of the curve, the two pumps can run safely and efficiently for a long time. If two pumps are stopped, only one pump is running in the system, and the working condition area (b1~b1′) of the pump is on the right of point d of the pump characteristic curve. The shaft power of the pump is very close to the rated power of the pump motor. Long-term operation under this condition will cause the motor to overheat, which is unsafe.

In the second example, it is a system with two pumps operating in parallel. If one pump is stopped and it becomes a single pump operation, its working condition area (b1~b1′) is on the right of point d, and the shaft power of the pump is very high. Close to the rated power of the pump motor, it is unsafe to run a single pump for a long time.

In the above two examples, generally do not use a single pump to run for a long time. Under special circumstances, if it is necessary to run a single pump for a long time, just close the pump outlet valve appropriately to increase the reading of the pump outlet pressure gauge. The working condition area (b1~b1′) of the pump will move to point d, the pump motor will not be overloaded, and the pump can run safely for a long time.

2. Pool pump problem for backwashing

In the past, many swimming pools were often equipped with a backwash pump. Now it seems that this investment can be saved. Without a special backwash pump, the filter tank can be back washed successfully. In the first example, the area of a single filter is 9.85㎡ and the backwash intensity is 12-15 L/S·㎡, which requires the pump to provide a backwash flow of 424~532 m3/h, because this flow is very close The Qd of the circulating pump is 520m3/h, so it is feasible to use a single water circulation pump for pool to realize the backwash of a single filter. In the second example, the area of a single filter is 3.14㎡, the backwashing intensity is 12-17L/S·㎡, and the required backwashing flow rate is 141~198m3/h. This flow rate is less than or equal to Qa=200m3/h. One circulating pump is suitable for backwashing a single filter.

Here we need to talk about how to adjust the backwash intensity by the way. Backwash intensity adjustment is actually to adjust the backwash flow rate. There are two specific operation methods: one is to install a flow meter before the backwash sewage discharge valve of the filter, open the sewage discharge valve during backwashing, and manually according to the flow meter data Control the opening of this valve to realize the adjustment of backwash intensity. The second is that if one filter is flushed while other filters are all closed and only one pump is running, then as long as the opening of the pump outlet valve is manually adjusted according to the value of the pump outlet pressure gauge, the backwash flow can be achieved ( Backwash intensity) adjustment.

3. Balanced pool recovers the energy problem of falling water head

When the counter-flow swimming pool water treatment equipment is operating normally, the height difference between the water level in the pool and the water level of the swimming pool is balanced, which is the geometric height of the circulating water pump. The greater the height difference, the greater the required head of the circulating water pump and the greater the power of the pump. If you do everything possible to reduce this height difference when designing a swimming pool, you can choose a circulating pump with a relatively low head, which is of great significance to the energy saving of swimming pools. When designing some swimming pools, a complete set of water treatment equipment, including equalization pools, are arranged in the basement of the overhead structure at the bottom of the pool, causing the height difference between the above two levels to reach more than 4m, and the energy of the water head falling from the overflow return tank pipeline is complete can not be recycled, causing a lot of waste. In Example 1, if the equalization pool can be deepened to 7m and the operating water level of the equalization pool reaches 5m, a circulating pump with a lower head of 2m can be used, which can save 10% of electricity. It can be seen that the equalization pool should not be placed at the bottom of the swimming pool but should be placed on the side of the swimming pool, and the height difference between the top of the equalization pool and the water level of the swimming pool should be controlled to be less than 1m, that is, to minimize the height of the falling water head. On the premise of ensuring the effective volume of the equalization pool, the area of the pool should be as large as possible to prevent the water level in the equalization pool from falling too much during operation.

4. Reduce the resistance of the plate heat exchanger

Plate heat exchangers are the most commonly used heating equipment for swimming pool water. However, the commercially available industrial plate heat exchangers have the characteristics of small flow, large temperature difference, and large resistance, and cannot meet the requirements of large circulating flow, small temperature difference, and low resistance in swimming pools. But so far there is no special heat exchanger for swimming pools, and almost all swimming pools still use this commercially available industrial plate heat exchanger. To reduce the heat exchange temperature difference and fluid resistance, a part of the circulating flow (1/5~1/3) of the water is heated by the plate heat exchanger and then mixed with the unheated water. Even if this method is adopted, the fluid resistance (pressure drop) will still be as high as 0.05Mpa, which is equivalent to the circulation pump with a head of 5m to overcome the resistance of this plate heat exchanger. To save this part of the energy, the pool pump manufacturer recommends the following method: when calculating the heat exchange area of the plate heat exchanger, determine the area of a single unit according to the heat exchange during the normal insulation operation of the swimming pool. A set of system should be equipped with two plate heat exchangers in the same area in this area. Two sets of plate heat exchangers must be used for the first heating operation of swimming pool water. In normal heat preservation operations, one set is sufficient for heat exchange. At this time, the pressure drop is 0.05. Mpa, but in order to reduce the fluid resistance, 2 sets are still opened at this time, the pressure drop is reduced to 0.025Mpa, so in the calculation of the total resistance of the system, the pressure drop of the plate change part can be calculated as 0.025Mpa so that the swimming pool is circulating When selecting the pump, the model with lower head can be considered. This method has been adopted in Example

1. For example, this method is also used in Example

2. Choosing a lower-lift circulating pump can save 20% of electric energy.