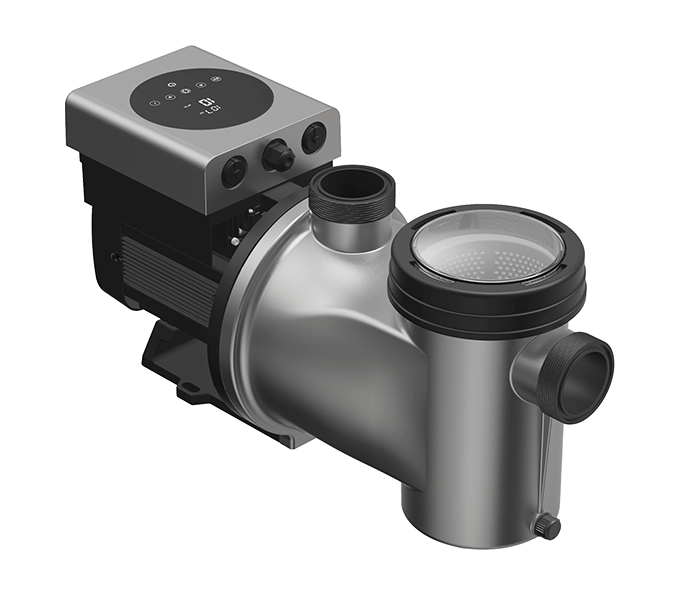

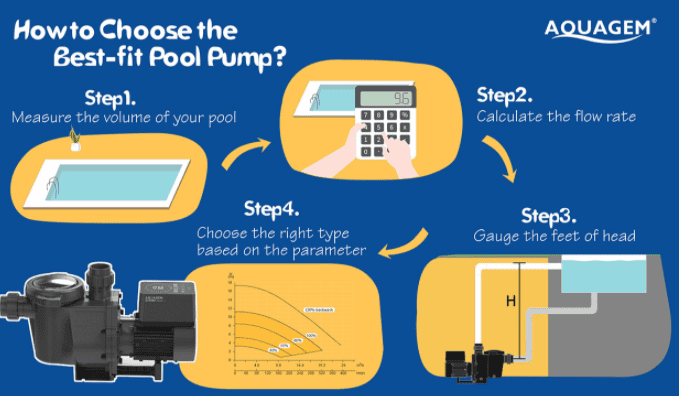

Swimming pool system.is as important as the human heart and plays a key role in ensuring water circulation in the swimming pool. It can drive the circulating water to the filter and other processing components to complete the purification of the swimming pool water. Therefore, the swimming pool filtration circulating water pump and the precautions when using it are extremely important.

Below is to share with you the pool filter pump requirements and precautions from a pool pump manufacturer.

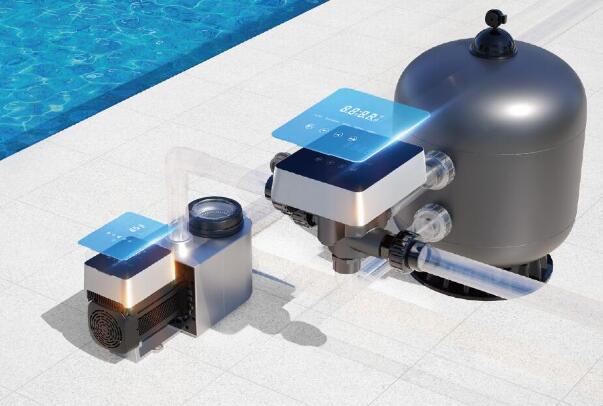

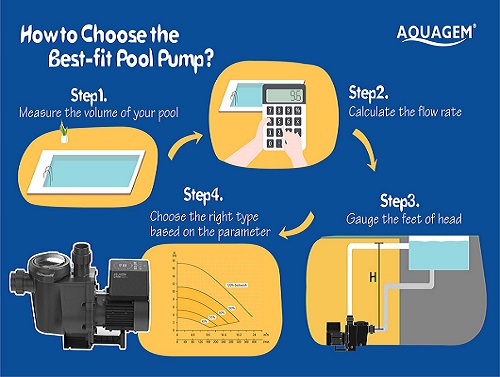

1. Pool filter pump is generally divided into the horizontal bearing centrifugal pump, plastic swimming pool water pump, massage water pump, etc. When we use it, the outlet of the water pump should be equipped with a pressure gauge, and the range of the pressure gauge should be 2-3 times the working pressure of the pump between. In addition, the water pool pump should be designed as a suction type and be located in the same pump room as the water treatment equipment and the dosing device.

2. Each group of swimming pool filter pump are supposed to have “working pump” and “standby pump”. The “working pump” and “standby pump” can be set manually, and at the same time, which prevent the pool filter pump from fatigue setting and start at regular intervals according to the owner’s requirements. At the same time, the constant temperature and disinfection booster water pool pump needs to be delayed after the circulation pump is started.

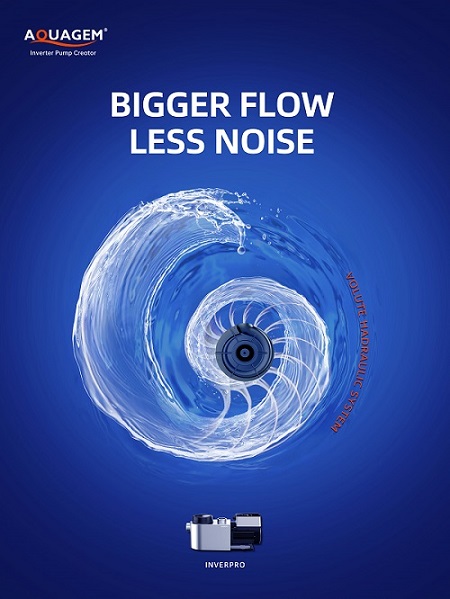

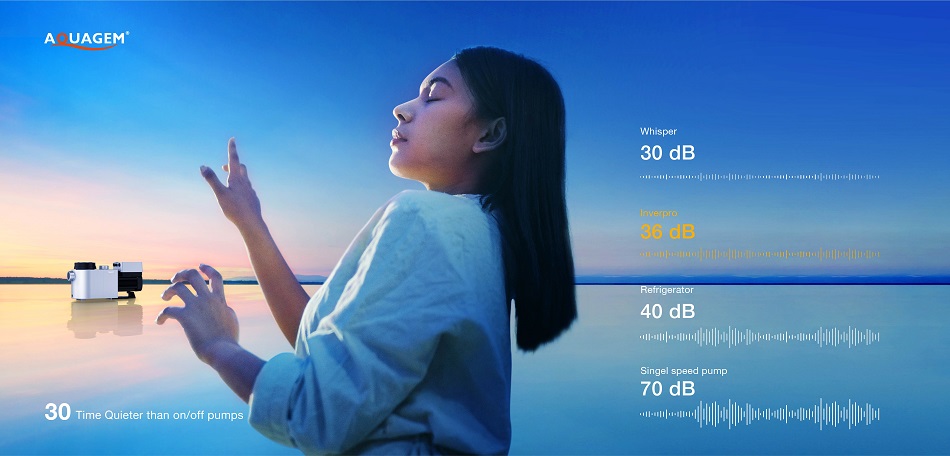

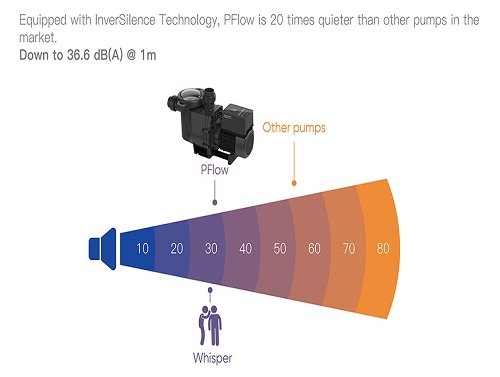

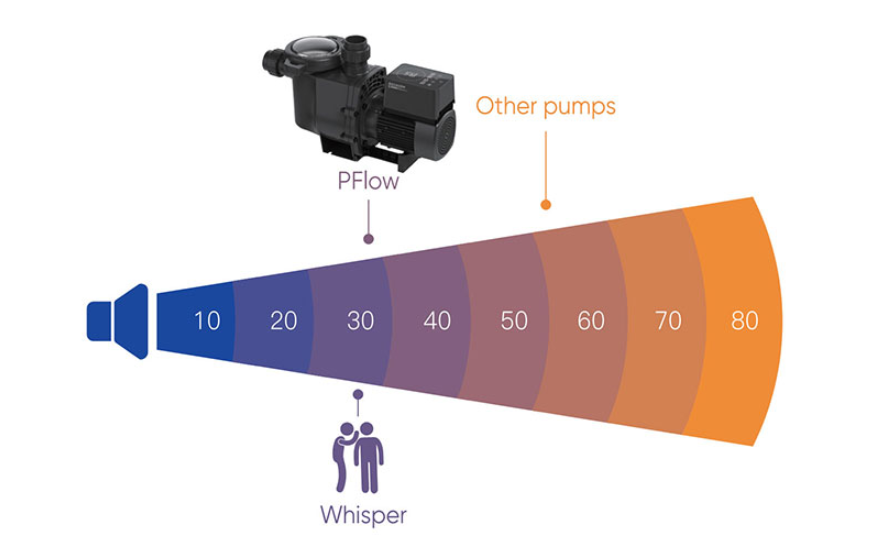

3. The noise and vibration generated during the operation of the swimming pool water pump are treated with shock absorption and noise reduction facilities. The pool pump control cabinet is equipped with an “automatic/manual control conversion device”. In the “automatic” working mode, when the “working pump” fails to work normally, the “standby pump” should be able to automatically start and put into operation. The water pump control cabinet can display the voltage/current/water pump’s “run”, “stop” and “fault” status/power supply’s “normal” or “fault” status parameters or information; and should be equipped with short-circuit protection/motor Overload protection/power supply voltage overvoltage or under voltage protection/low water level protection device.

Precautions for daily maintenance of swimming pool water pump

For swimming pool managers, in addition to regular daily water treatment work, it is also necessary to maintain the swimming pool equipment, otherwise, it is easy to cause damage to the equipment, affect the effect of water treatment, and the normal use of the swimming pool.

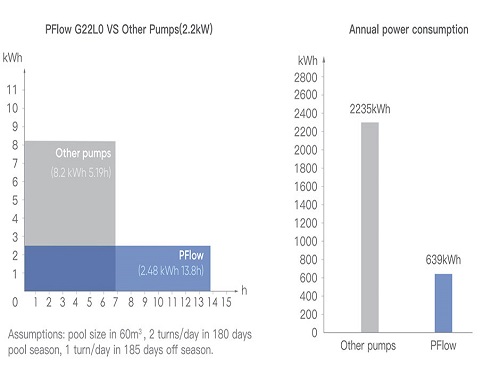

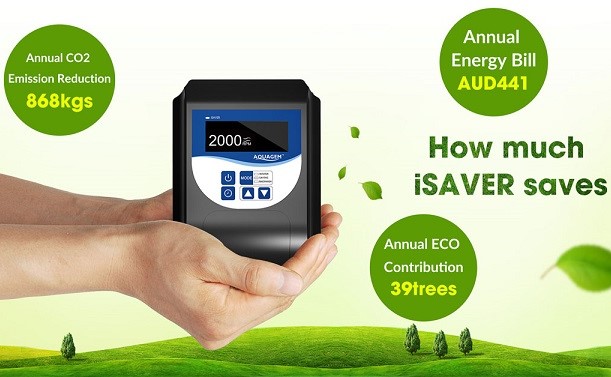

The water circulation pump for pool is a hydraulic machine that transports water to a distance with the help of power equipment and transmission devices. It plays an important role in the water treatment of the swimming pool. In order to improve the work efficiency of the pool pump and ensure the normal operation of the water treatment system, we can wholesale the most energy-efficient pool pump, additionally, we need to clean and maintain the filter basket regularly, check the pool pump head cover sealing ring, etc., and master the correct energy-saving pool pump usage and maintenance method.

1. Daily records. Check the swimming pool pump regularly and establish a running record, including running time, whether there is abnormal noise and vibration, flow conditions, current and voltage, and whether the motor temperature is normal, etc. In case of failure, it is necessary to record the location of the failure, its cause, and analyze the discharge.

2. Before running the swimming pool water pump, make sure to check whether the hair collector is filled with water to confirm that the suction port has sufficient suction.

3. Before starting the pool water pump, check whether the inlet valve and outlet valve are open to prevent damage to the pool pump.

4. In order to prevent the pool pump from clogging and affecting the use, check the pump head cover sealing ring, etc., and clean the filter basket of the hair filter in time. When cleaning, first stop the pool pump, then close the ball valves on the inlet and outlet pipes of the system and the swimming pool, then open the transparent cover to clean the filter basket, then install the transparent cover, open the ball valve, and finally start the swimming pool circulation pump again.

5. When performing mechanical maintenance, be sure to disconnect the power supply of the pool circulation pump.

6. When the pool circulation pump is not used for a long time in winter, the water in the pump must be drained fully.

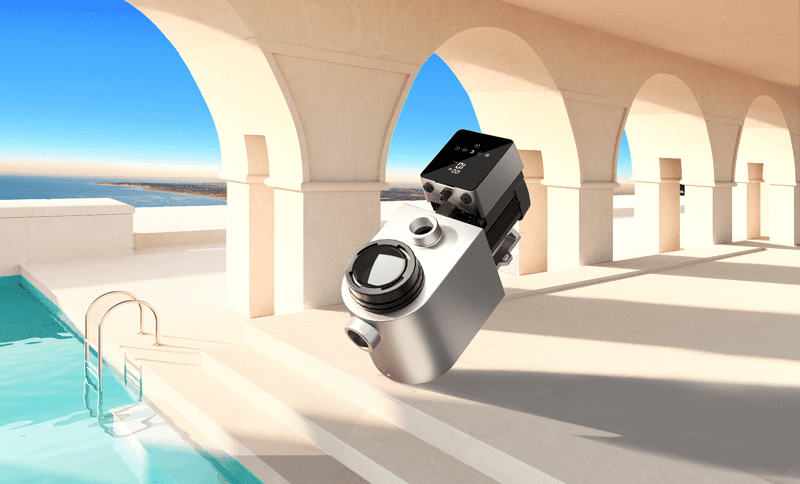

There are many components of swimming pool equipment. Managers must do a good job in the maintenance of these pool circulation pumps to avoid damage to the equipment and not use the pool pump. Besides, a pool inverter pump from a competitive pool pump manufacturer is recommended to decrease noise and save energy consumption.